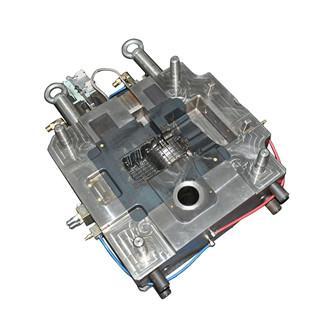

Because of my extensive experience in the design of die-casting molds for aluminum alloys, I have a profound understanding that the design of the die-casting mold for aluminum alloys must have a reasonable structure and be simple to operate in order to determine whether or not it is capable of producing workpieces that meet the required standards and whether or not the newly developed products have the potential to be successful. This is because the design of the die-casting mold for aluminum alloys must be able to determine whether or not the newly developed products have the potential to be successful.

Nevertheless, we must not neglect to acknowledge the significance of it. If I were to choose between a single-process mold structure and a composite mold structure, which would be more advantageous for me? In many manufacturing companies, the use of this method is a common practice. This is due to the fact that the requirements for machining accuracy are not particularly high, and the production batches of workpieces are not particularly large. When to use a formal mold structure and how to determine when to use it1. The structural peculiarities and characteristics of the formal mold construction.

The concave mold is installed on the lower mold base within the formal mold; this is done within the mold. This is the specific structural feature that distinguishes the formal mold. As a consequence of this, it is not necessary to take into account cable clamp kit the flow direction of the workpiece or waste material when coming up with the design for the formal mold. The following are two of the benefits that come with developing a formal mold structure: The structure of the mold is straightforward, which makes it possible to shorten the manufacturing cycle of the mold. This is beneficial for the pursuit of new product research and development because it allows for the mold to be manufactured more quickly.

The mounting and adjustment of the gap between the convex and concave China die casting manufacturer is a more straightforward process when compared to the process of using flip-chip molds. It is important to note that the formal mold structure is associated with three drawbacks. The first drawback is that the small expansion force in the die hole is increased when there is an accumulation of workpieces or waste materials in the die hole. This is the first disadvantage.

Increasing the wall thickness of the die is required in order to accomplish the goal of achieving the desired level of strength. It is possible that the back hole, which is also referred to as the discharge hole, of the die edge will need to be processed according to certain conditions. The mold production cycle is lengthened as a result of this process, which also results in an increase in the fees associated with mold processing. In the event that the formal mold structure is unable to satisfy the technical requirements of the workpiece, it is only at that point that other types of mold structures can be considered as potential alternatives. The appropriate time to choose a structure that is designed for flip-chip moldsThe following elements constitute the structural characteristics of the flip-chip mold:

We are required to make use of a spring pressure unloading device in order to remove the workpiece or waste from the punch. This is because the punch is installed on the lower mold base, which means that we are unable to remove it without the device. This means that there is a problem with how to discharge the workpiece or waste piece that is located in the concave hole from the hole. Additionally, the concave mold of the flip-chip mold is installed on the upper mold base, which means that there is a problem with how to discharge the workpiece. There are two distinct benefits associated with the flip-chip mold structure.

The utilization of a spring-pressure unloading device during the punching process results in workpieces that are smooth and have a high surface quality. This is due to the fact that the process produces workpieces.

The workpiece or waste material does not accumulate in the die hole because the knocking rod is used to knock it out of the die hole. This removes the possibility of the workpiece or waste material becoming stuck in the die hole. It is possible that this will lessen China die casting manufacturer the tensile force that the waste material from the workpiece exerts on the hole, which will result in a thinner wall thickness for the die die.In order to implement the knocking rod, the knocking rod is utilized.

It is possible to reduce the amount of wear on the die edge that is caused by the workpiece or waste material because the workpiece or waste material does not accumulate in the die hole. Additionally, the number of times that the die needs to be sharpened can be decreased, which leads to an increase in the die's level of service life.

It is not necessary to process the reverse hole of the die, which is also referred to as the discharge hole. This is due to the fact that workpieces or waste materials do not accumulate in the die hole. This eliminates the need to process cable clamp kit the discharge hole, which can result in a reduction in the costs associated with mold processing and a shortening of the cycle time for the production of the mold.

The blank holder force is appropriate for stretching the rotating body because it only acts prior to the flat blank being completely pulled into the die. This makes it suitable for stretching the body. It is because of this that the blank can be stretched when it is stretched. In relation to the structure of the flip-chip mold, there are three drawbacks that are associated with it:(1) The mold structure is relatively complicated (in comparison to formal molds); (2) It is challenging to install and adjust the gap between the convex and concave molds (in comparison to the formal mold); and (3) It is difficult to remove workpieces or waste materials (it is recommended to use compressed air to blow them away).

When the time is right, selecting a mold structure that only requires a single process. The single-process mold structure is associated with three drawbacks die casting, which are and are as follows:(1) the components do not possess a high level of precision; (2) the performance of the production process is not very efficient. There are four guiding principles that should be followed when selecting structures for single-process molds.

In conclusion, it is evident that the utilization of single-process molds is more suitable for certain workpieces that have low precision requirements and small production batches. This is the case because single-process molds are more economical. In light of the fact that our country is currently in the process of implementing a socialist market economy, the creation and development of new products is of the utmost importance for our country. This is especially true in light of the fact that our nation is currently in the same process. The significance of this matter cannot be overstated for any and all businesses. When it comes to rapidly occupying the market, the only products that are capable of doing so are those that are developed in this manner. Molds that are manufactured through a single process are able to better fulfill this requirement at this point, which gives the impression that they are more practical. It is impossible to achieve perfection in our lives. It is imperative that we do not take the rules at face value and instead apply them in a mechanical fashion.