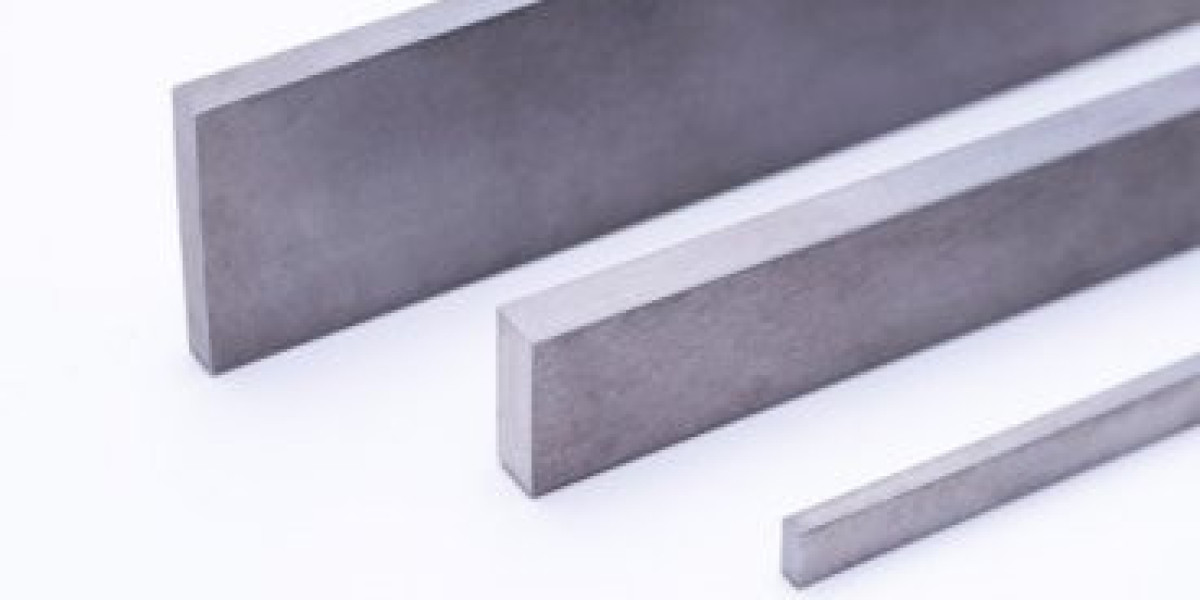

In the world of manufacturing and machining, precision and durability are key. Cemented Carbide Strips, also known as carbide strip and tungsten carbide strips, have become the go-to material for various industrial applications due to their hardness and wear resistance. Shanghai Diatooling, with its state-of-the-art technology and commitment to quality, stands out as a leading manufacturer and provider of these high-performance materials. In this blog, we explore the intricacies of Cemented Carbide Strips and how Shanghai Diatooling's offerings can elevate your manufacturing processes.

The Essence of Cemented Carbide Strips

Cemented Carbide Strips are composite materials consisting of fine particles of tungsten carbide (WC) and cobalt (Co) binder. The unique combination of these elements results in a material with exceptional hardness and strength, making it ideal for cutting, drilling, and wear-resistant applications.

Why Choose Shanghai Diatooling for Your Carbide Strip Needs?

Superior Technological Background

Shanghai Diatooling's advanced manufacturing processes ensure that every carbide strip is produced to the highest standards, providing customers with reliable and consistent quality.

Outstanding R&D Capability

The company's research and development team is at the forefront of innovation, constantly refining and improving the properties of Cemented Carbide Strips to meet the evolving needs of the industry.

Commitment to Strict Quality

Shanghai Diatooling's dedication to quality control ensures that every strip of carbide they produce meets the stringent requirements of their clients, providing a product that is second to none.

Applications of Cemented Carbide Strips

Cutting Tools

Carbide strips are widely used in the manufacturing of cutting tools due to their ability to maintain a sharp edge and resist wear, even under high-pressure conditions.

Wear Parts

In industries where components are subjected to abrasive materials, tungsten carbide strips serve as an excellent choice for wear parts, extending the service life of machinery.

Drilling and Milling

The hardness and strength of https://www.diatooling.com/cemented-carbide-strip.htmlmake them perfect for creating durable drills and milling tools that can withstand the rigors of heavy-duty machining.

Benefits of Using Cemented Carbide Strips

Longevity: The superior hardness of carbide strips means they last longer than traditional materials.

Precision: The uniformity of the material ensures consistent precision in cutting and drilling operations.

Cost-Effectiveness: While the initial cost may be higher, the extended life and reduced need for replacements make carbide strips a cost-effective choice in the long run.

How to Select the Right Carbide Strip

When choosing tungsten carbide strips, consider the following factors:

Material Composition: The ratio of tungsten carbide to cobalt can affect the hardness and toughness of the strip.

Size and Shape: Select the dimensions that best fit your specific application requirements.

Quality Assurance: Look for manufacturers with a proven track record of quality control, like Shanghai Diatooling.

The Manufacturing Process of Cemented Carbide Strips

Understanding the manufacturing process of carbide strips can provide insight into why they perform so well in various applications:

Powder Mixing: Tungsten carbide and cobalt powders are mixed in precise proportions.

Pressing: The powder mixture is pressed into the desired shape under high pressure.

Sintering: The pressed shape is heated to a temperature where the cobalt binds the tungsten carbide particles together.

Grinding and Finishing: The sintered strip is ground and finished to achieve the required dimensions and surface finish.

Conclusion

Cemented Carbide Strips, with their exceptional properties, have become indispensable in modern manufacturing. Shanghai Diatooling's commitment to excellence in production and quality ensures that their carbide strips are the top choice for precision and durability. Whether you're in need of carbide strips for cutting tools, wear parts, or drilling and milling applications, look no further than the high-quality tungsten carbide strips provided by Shanghai Diatooling.

Shanghai Diatooling is a highly professional and experienced carbide preforms manufacturer and provider. With the superior technological background, outstanding R&D capability, and the concept of insisting on strict quality, we can offer excellent service and large capacity manufacture.And with our vast experience in tungsten carbide, every customer is sure to get the right solution for their cutting tools.

Welcome to contact us if you need to know more about Cemented Carbide Strips details or order wholesale.