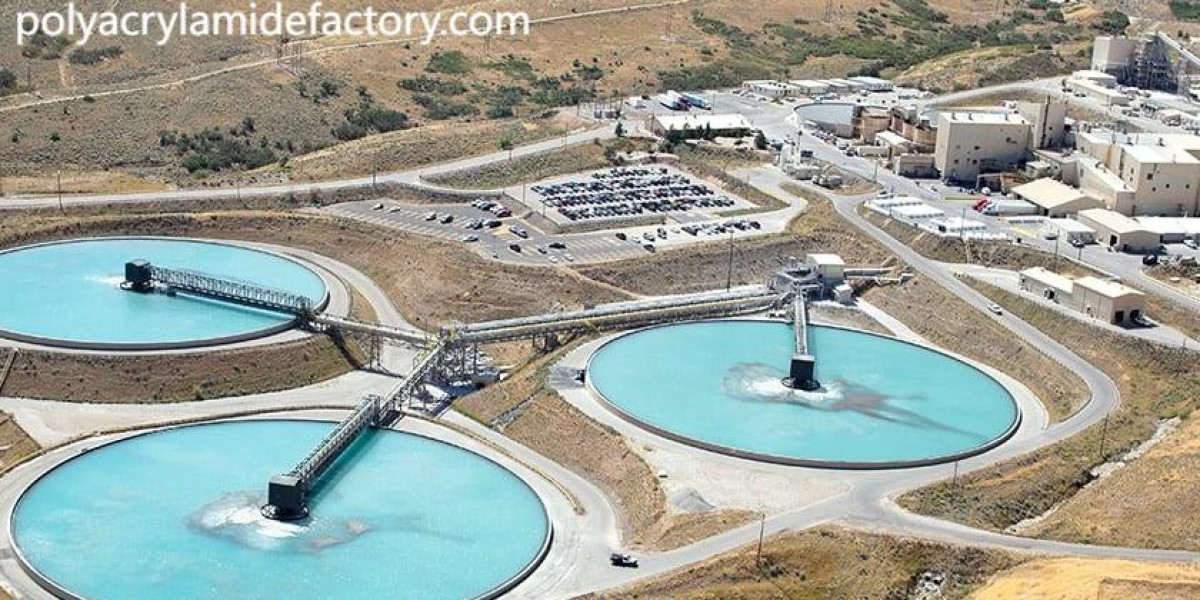

In the mining sector, mineral processing flocculant Manufacturers play a vital role in optimizing resource recovery and environmental compliance. Jiangsu Hengfeng Fine Chemical Co., Ltd., a leader in polymer solutions, specializes in advanced polyacrylamide (PAM) formulations tailored for ore concentration, wastewater treatment, and tailings management. These products enhance sedimentation efficiency, reduce water consumption, and ensure compliance with stringent discharge standards.

Hengfeng’s expertise lies in developing application-specific flocculants. For example, anionic PAM variants effectively separate silica and clay particles in coal processing, while cationic types improve sludge dewatering in copper or gold mines. Their production processes incorporate microbial nitrile hydratase technology, achieving monomer purity exceeding 99% and molecular weight control between 5–30 million, ensuring adaptability to diverse mineral compositions.

The company’s ISO-certified facilities produce 50,000 tons annually, supported by a dedicated R&D team of 52 experts. Recent innovations include low-VOC emulsion formulations for high-salinity environments and closed-loop water recycling systems, reducing environmental impact[[43][80]]. Case studies highlight successes in Southeast Asian nickel mines, where Hengfeng’s flocculants increased solid-liquid separation rates by 40%, and in Chilean copper operations, where tailings turbidity dropped by 60%.

Sustainability remains a priority. By minimizing chemical residue in treated water and optimizing energy use during polymerization, Hengfeng aligns with global green mining initiatives. Their dynamic testing labs also offer customized solutions for rare earth mineral processing, addressing challenges like fine particle stability and acidic wastewater.

For engineers and procurement specialists seeking reliable technical resources, www.polyacrylamidefactory.com provides comprehensive guides on flocculant selection, molecular weight optimization, and case studies across 60+ countries. This platform bridges cutting-edge polymer science with practical industrial needs, fostering sustainable and efficient mineral extraction worldwide.