Understanding Sound Attenuated Generator Enclosures

In today's world of rising industrial demand and urban expansion, sound pollution control has become a crucial necessity. A sound attenuated generator enclosure is an advanced solution designed to reduce the noise emitted by diesel or gas generators. These enclosures offer an effective way to contain operational sounds while maintaining proper ventilation and generator functionality. They are essential in settings such as hospitals, data centres, construction sites, manufacturing plants, and residential areas.

Key Features of a Sound Attenuated Generator Enclosure

To ensure optimal noise control and performance, sound attenuated enclosures integrate several high-grade components and technologies:

- Heavy-duty acoustic insulation using mineral wool or foam panels

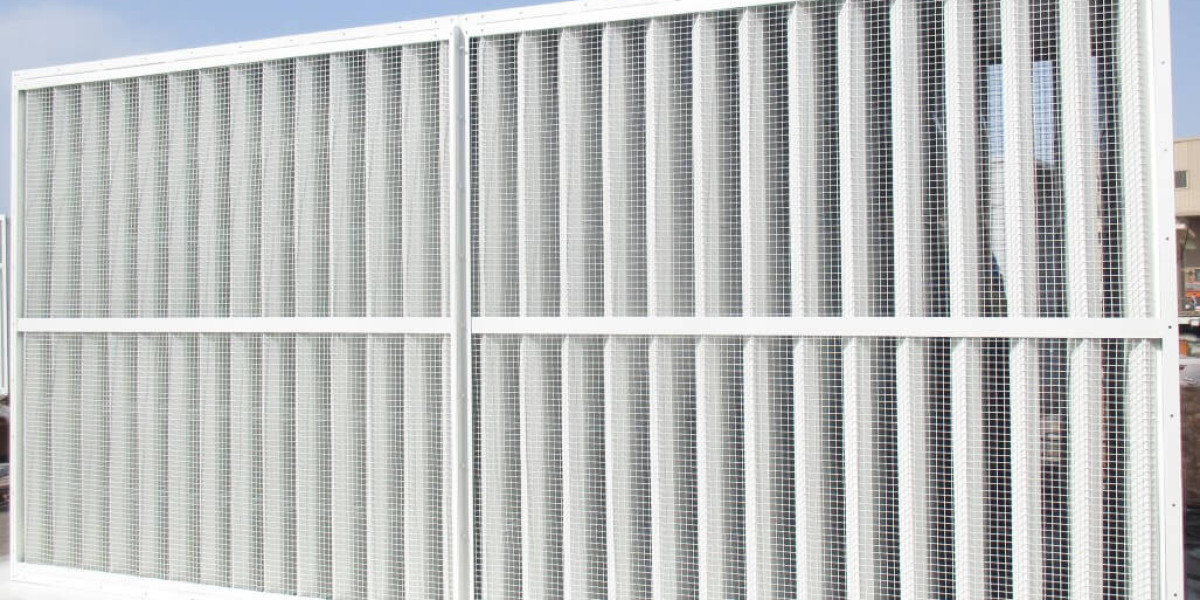

- Louvered air intake and exhaust systems for airflow without compromising soundproofing

- Weatherproof and corrosion-resistant structures

- Industrial-grade silencers for exhaust and air outlets

- High-performance vibration isolators to reduce structural sound transmission

- Custom ductwork that enhances airflow while minimizing noise

- Easy-access doors and panels for regular generator maintenance

These enclosures are carefully engineered to achieve sound levels as low as 65–75 dBA at 1 meter, depending on the generator capacity and site conditions.

Benefits of Installing a Sound Attenuated Generator Enclosure

Deploying a sound attenuated enclosure is more than just regulatory compliance—it delivers multiple performance, safety, and business benefits:

Noise Control Compliance

Meeting local environmental regulations is a critical concern. These enclosures help organizations adhere to noise control standards in urban and industrial zones.

Enhanced Worker Safety and Comfort

By minimizing harmful noise exposure, they contribute to a safer and more comfortable workplace, reducing the risk of hearing loss and improving communication efficiency.

Improved Equipment Longevity

Enclosures protect generators from dust, rain, and temperature fluctuations, significantly extending the lifespan of the equipment.

Operational Continuity in All Weather Conditions

The weather-resistant design ensures that generators can function efficiently without interruptions, even in extreme environmental conditions.

Construction Materials and Engineering Design

A high-performance soundproof generator enclosure is the result of meticulous design and material selection:

- Galvanized or powder-coated steel for rust resistance

- Acoustic foam or high-density rock wool insulation to absorb noise

- Seamless welding and gaskets to prevent sound leakage

- Double-layer walls with air gaps to enhance sound-dampening

- Custom-engineered silencers for air intakes and exhausts

Advanced computational fluid dynamics (CFD) models are often used to simulate airflow and thermal performance to optimize the design before fabrication.

Applications Across Diverse Sectors

Sound attenuated enclosures are used across various industries due to their flexibility and reliability:

- Healthcare Facilities: Where silence is critical, especially near ICUs and emergency units

- Data Centers: To protect sensitive servers from both noise and heat

- Construction Projects: For urban or nighttime work to minimize public disturbances

- Oil & Gas Installations: Offering safe, compliant, and robust acoustic control

- Commercial Buildings and Residential Towers: Maintaining peaceful surroundings without power interruptions

Customization Options for Project-Specific Requirements

Every project comes with its own acoustic, spatial, and environmental needs. That’s why custom sound attenuated enclosures are engineered with precision:

- Tailored dBA reduction levels

- Skid-mounted or containerized formats

- Integration with automatic transfer switches (ATS)

- Remote monitoring and control systems

- Fire suppression and thermal management systems

- Colour-coded finishes or branding requirements

Engineers evaluate factors such as generator size, site constraints, ventilation requirements, and ambient noise levels to design enclosures that deliver both function and compliance.

Ventilation and Cooling Considerations

Efficient thermal management is vital to avoid overheating inside the enclosure. This is achieved through:

- Forced air ventilation systems

- Low-noise axial fans

- Temperature-controlled louver systems

- Heat recovery solutions

Baffles and acoustic louvers are designed to prevent direct line-of-sight for sound escape, while still ensuring sufficient airflow for combustion and cooling.

Installation and Maintenance Practices

For optimal performance and longevity, proper installation and periodic maintenance are non-negotiable:

- Level surface placement to avoid vibration-induced fatigue

- Sealing of cable and fuel entry points to avoid noise leakage

- Routine inspection of acoustic materials for degradation

- Lubrication and servicing of fan motors and silencers

- Monitoring for rust, corrosion, or weather damage

Preventive maintenance schedules ensure that both the generator and the enclosure operate efficiently with minimal downtime.

Why Choose a Professionally Engineered Sound Attenuated Enclosure?

Choosing a professionally designed enclosure ensures superior performance, greater compliance, and lower total cost of ownership. Unlike generic or DIY enclosures, expert-built models:

- Are tested for certified acoustic performance levels

- Meet international noise and safety standards (e.g., ISO 8528-10)

- Feature modular construction for future scalability

- Include full documentation, schematics, and load data

- Offer after-sales support and warranty options

Investing in high-quality engineering translates to reduced risk, superior noise abatement, and dependable operation under all conditions.

How to Select the Right Manufacturer or Supplier

When sourcing a sound attenuated generator enclosure, consider the following criteria:

- Experience in industrial noise control

- Capability to provide turnkey solutions (design, supply, and install)

- Use of certified and tested acoustic materials

- Customer reviews and case studies

- Compliance with ISO and local regulatory codes

- Post-sales support, AMC, and emergency services

Suppliers who offer end-to-end services—from site survey to commissioning—provide added value and peace of mind.

Conclusion

A sound attenuated generator enclosure is a mission-critical asset for any facility that relies on standby or continuous generator power. By dramatically reducing noise emissions, protecting equipment, and ensuring compliance with environmental regulations, these enclosures play a pivotal role in modern infrastructure.

Whether your project is a high-rise tower, industrial plant, or remote oilfield, choosing a well-engineered acoustic enclosure ensures that power continuity doesn't come at the expense of peace, safety, or compliance.