Tooling and fixture introduction:

Tooling fixture is a process device used to quickly fasten the workpiece during processing, so that the machine tool, cutting tool, and workpiece maintain the correct relative position. That is to say, Workholding fixture is an indispensable part of machining. Driven by the development of machine tool technology towards high-speed, high-efficiency, precision, composite, intelligence, and environmental protection, fixture technology is moving towards high-precision, high-efficiency, modular, combined, and universal , Economic development.

Fixtures are also called fixtures. Broadly speaking, in any process in the process, a device used to quickly, conveniently and safely install a workpiece can be called a fixture. For example, welding fixtures, inspection fixtures, assembly fixtures, machine tool fixtures, etc. Among them, machine tool fixtures are the most common, often referred to as fixtures for short.

When processing a workpiece on a machine tool, in order to make the surface of the workpiece meet the technical requirements of the size, geometric shape and mutual position accuracy with other surfaces specified in the drawing, the workpiece must be installed (positioned) and clamped (clamped) before processing .

The application of machine tool fixtures is beneficial to ensure the processing accuracy of workpieces and stabilize product quality; it is beneficial to improve labor productivity and reduce costs; it is beneficial to improve workers' working conditions and ensure safe production; it is beneficial to expand the range of machine tools and realize "one machine with multiple uses".

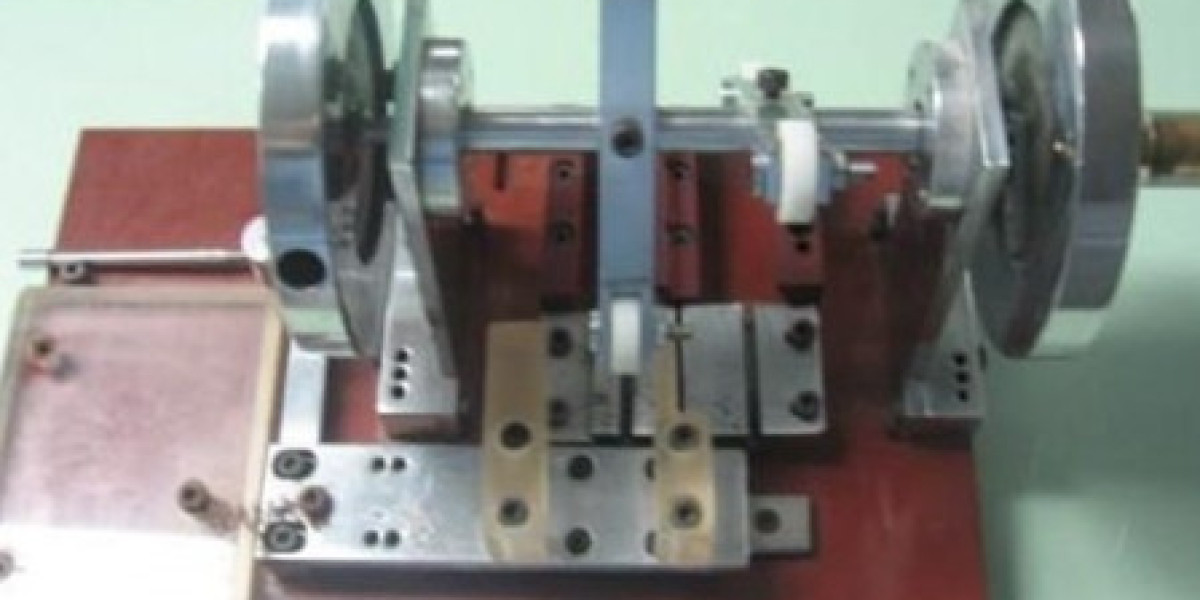

The fixture usually consists of a positioning element (to determine the correct position of the workpiece in the fixture), a clamping device, a tool setting guide element (to determine the relative position of the tool and the workpiece or to guide the direction of the tool), an indexing device (to enable the workpiece to be installed in one installation) To complete the processing of several stations, there are two types of rotary indexing device and linear moving indexing device), connecting elements and clamp concrete (fixture base).