Explore the Future of Personalized Medicine with Renub Research’s Latest Insights

? Access Full Report on 3D Printing in Healthcare Market

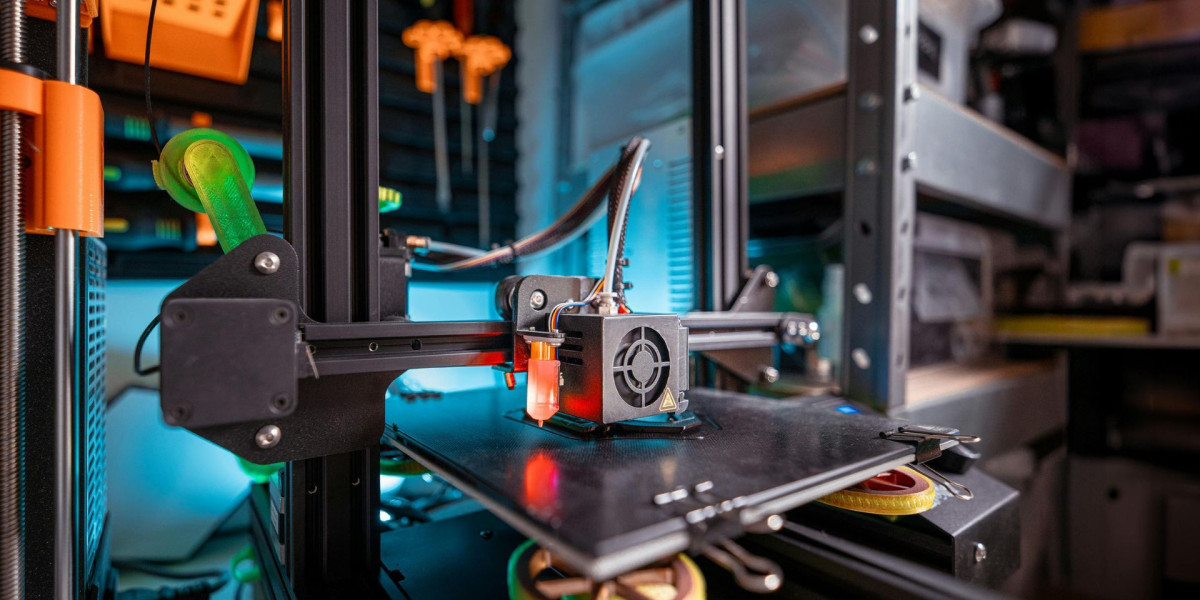

The Future of Healthcare is Being Printed Layer by Layer

The global 3D printing in healthcare market is rapidly transforming the medical landscape by offering innovative solutions in surgical planning, prosthetics, bioprinting, and patient-specific treatment. According to Renub Research, this dynamic market is poised for substantial growth, driven by technological advancements, cost reductions, and increased adoption across hospitals, clinics, research labs, and academic institutions.

What was once considered futuristic is now becoming a clinical reality. From printing custom implants to developing tissue models for complex surgeries, 3D printing is ushering in a new era of personalized and precise medical care.

Key Drivers Behind Market Expansion

Customization and Personalization

One of the biggest strengths of 3D printing in healthcare is its ability to create tailored solutions for individual patients. Whether it’s a cranial implant, a dental crown, or an orthopedic device, 3D printing enables doctors to design anatomically accurate tools that fit the unique physiology of each patient. This personalized approach leads to better surgical outcomes, faster recovery, and enhanced patient satisfaction.

Surge in Surgical Planning and Training Tools

Medical professionals are leveraging 3D-printed anatomical models for pre-surgical planning and education. Surgeons can now practice procedures using patient-specific models, reducing intraoperative risks and boosting confidence. In educational settings, 3D-printed organs and body parts provide realistic, tactile experiences that enhance learning for medical students.

Rapid Prototyping and Reduced Costs

Traditional manufacturing of medical devices can be time-consuming and expensive, especially during the prototyping phase. 3D printing allows for rapid iterations at a lower cost, enabling faster innovation. Small and medium-sized enterprises (SMEs) in med-tech are particularly benefiting from the affordability and speed of additive manufacturing.

Innovation in Bioprinting

Though still in the early stages, bioprinting human tissues and organs has the potential to revolutionize transplants and regenerative medicine. Research institutions and biotech companies are working on printing living cells to form tissues like skin, cartilage, and even functional organs in the future. While regulatory approvals are pending, this area represents one of the most exciting frontiers in medical science.

Applications Across Multiple Medical Fields

The scope of 3D printing in healthcare is extensive and expanding, with practical applications in areas including:

Orthopedics: Custom braces, prosthetics, and surgical tools.

Dentistry: Implants, aligners, and bridges tailored to individual oral anatomy.

Cardiology: 3D models of hearts for congenital defect analysis and surgical planning.

Oncology: Tumor models to study cancer growth and test drug efficacy.

Pharmaceuticals: 3D-printed drugs with personalized dosages and release profiles.

Hearing Aids: Rapid customization and scaling of production.

As medical professionals and researchers continue to discover new use cases, 3D printing is becoming indispensable across hospitals, specialty clinics, and research labs.

Growing Investment and Government Support

Governments and private investors alike are recognizing the potential of 3D printing in healthcare. Numerous public health initiatives now include funding for 3D printing research and infrastructure, especially in countries focusing on healthcare modernization. Startups and established players are receiving grants and investments to further develop next-generation healthcare solutions using 3D printing.

Additionally, regulatory agencies such as the FDA (U.S. Food and Drug Administration) are increasingly working to establish clear pathways for the approval of 3D-printed medical devices and drugs, fostering trust and adoption in the healthcare community.

Technological Innovations Enhancing Capabilities

Recent advancements in materials, hardware, and software are making 3D printing more precise, scalable, and applicable to clinical settings. Innovations include:

High-resolution 3D printers capable of printing complex geometries.

Biocompatible materials that safely integrate with human tissue.

AI-powered modeling software that generates optimized designs based on patient scans.

These developments are reducing barriers to entry, enabling wider adoption across healthcare organizations, and fostering a wave of innovation.

Regional Insights: North America Leads, Asia-Pacific Emerging Rapidly

North America dominates the 3D printing in healthcare market due to robust infrastructure, advanced research facilities, and strong regulatory frameworks. The U.S., in particular, is home to leading medical device companies and a high rate of technology adoption in hospitals.

Europe follows closely, with countries like Germany, the UK, and France investing in healthcare R&D and technology upgrades. The European Union’s commitment to innovation in healthcare also plays a pivotal role.

Meanwhile, Asia-Pacific is emerging as a key growth region. Countries like China, Japan, South Korea, and India are rapidly investing in healthcare technology and expanding their digital infrastructure. With growing healthcare demand and a large patient base, Asia-Pacific holds immense potential for 3D printing applications.

Industry Challenges and Roadblocks

Despite its immense potential, the 3D printing in healthcare market faces some challenges:

Regulatory Complexity: Approval processes for 3D-printed devices and biologics can be lengthy and complex.

Material Limitations: The availability of medical-grade, biocompatible materials is still evolving.

Skill Gaps: Healthcare providers often lack the in-house expertise to operate 3D printing technologies.

High Initial Costs: While long-term savings are clear, initial setup costs can be high for smaller hospitals or clinics.

Addressing these challenges requires continued collaboration between regulators, technology providers, academic institutions, and healthcare professionals.

The Future Outlook: A Convergence of Tech and Healthcare

The future of the 3D printing in healthcare market looks extremely promising. As technology matures, costs decline, and acceptance grows, 3D printing is expected to become standard practice in several medical domains. The ability to offer customized, efficient, and patient-friendly care is revolutionizing how medical treatments are designed and delivered.

With increasing digitization of healthcare, integration of AI, IoT, and machine learning with 3D printing will further streamline workflows, automate diagnostics, and enhance patient care. Organizations that invest in these technologies today will lead the healthcare of tomorrow.

New Publish Report:

- Japan Flexible Packaging Market Outlook 2025–2033

- Japan Cataract Surgery Devices Market Trends 2025–2033

- Japan Ultrasound Device Market – Imaging Trends & Forecast 2025–2033

About the Company

Renub Research is a Market Research and Consulting Company with more than 15 years of experience, especially in international Business-to-Business Research, Surveys, and Consulting. We provide a wide range of business research solutions that help companies make better business decisions. We partner with clients across all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

Our wide clientele includes key players in Healthcare, Travel & Tourism, Food & Beverages, Power & Energy, Information Technology, Telecom & Internet, Chemicals, Logistics & Automotive, Consumer Goods & Retail, Building & Construction, and Agriculture. Our core team comprises experienced professionals with graduate, postgraduate, and Ph.D. qualifications in Finance, Marketing, Human Resources, Bio-Technology, Medicine, Information Technology, Environmental Science, and more.

Media Contact

Company Name: Renub Research

Contact Person: Rajat Gupta, Marketing Manager

Phone No: +91-120-421-9822 (IND) | +1-478-202-3244 (USA)

Email: rajat@renub.com

Website: https://www.renub.com/3d-printing-in-healthcare-market-p.php