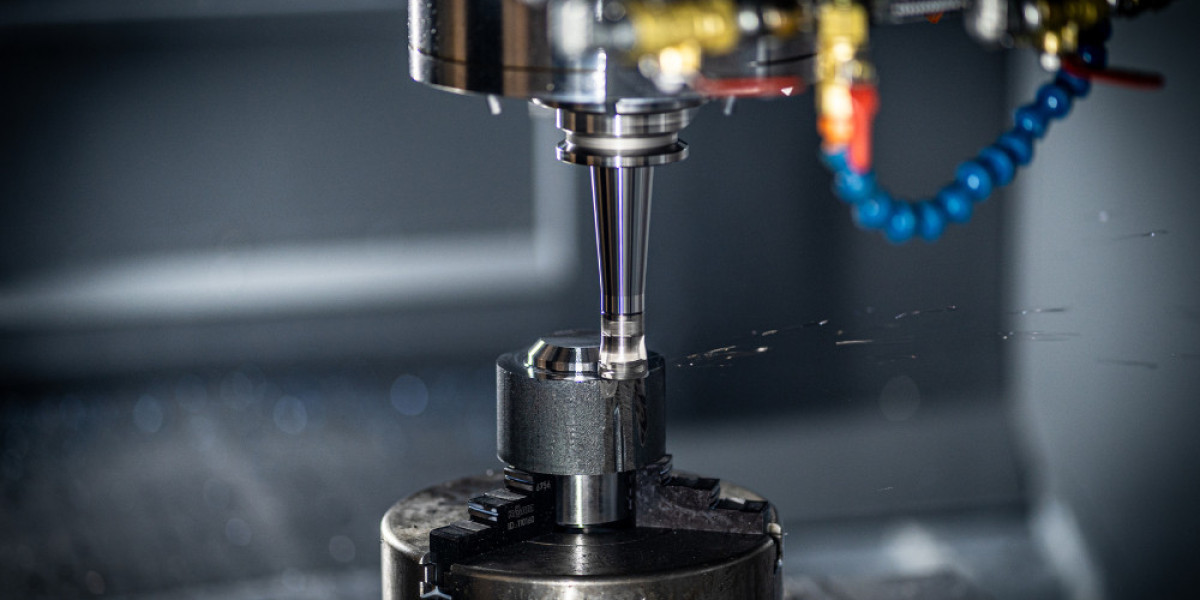

CNC (Computer Numerical Control) turning is a fundamental process in precision machining, involving the rotation of a workpiece against a stationary cutting tool. The process is primarily used to create cylindrical components, such as shafts, pins, and bushings. Custom Cnc turning services cater to specific design and production requirements, offering highly accurate and repeatable results across various industries.

Whether it’s for aerospace, automotive, medical, electronics, or industrial applications, custom CNC turning ensures your components meet exact specifications, tight tolerances, and high surface finish requirements.

What Are Custom CNC Turning Services?

Custom CNC turning services refer to the tailored machining of parts using CNC lathes and turning centers. Unlike off-the-shelf or mass-produced parts, custom CNC-turned components are designed and fabricated to meet specific customer requirements, including dimensions, material selection, tolerances, finishes, and production volumes.

These services are ideal for:

Prototyping and product development

Short to medium production runs

High-precision, complex geometries

Low-volume, high-mix manufacturing

Key Capabilities of Custom CNC Turning

1. Multi-Axis CNC Turning

Custom services often utilize multi-axis CNC lathes, including 2-axis, 3-axis, and even up to 9-axis machines. Multi-axis lathes allow for the production of complex components in a single setup, reducing cycle times and improving accuracy.

2. Tight Tolerance Machining

Custom CNC turning is capable of maintaining tolerances as tight as ±0.0002 inches, depending on the material and part complexity. This is especially crucial in industries such as aerospace, medical, and defense.

3. Live Tooling Capabilities

Advanced CNC turning centers come equipped with live tooling (milling, drilling, tapping, etc.), allowing for additional operations beyond turning without the need for secondary machining, saving time and cost.

4. Rapid Prototyping

For product development and innovation, rapid prototyping with CNC turning allows for the fast production of functional prototypes that accurately represent the final product.

Materials Used in CNC Turning

Custom CNC turning services support a wide range of materials, including:

Metals: Aluminum, steel, stainless steel, brass, copper, titanium, Inconel, and more.

Plastics: Delrin, nylon, PEEK, PTFE, ABS, and polycarbonate.

Exotic Alloys: Hastelloy, Monel, and other specialized materials for high-performance applications.

Each material presents unique machinability challenges, and experienced machinists optimize cutting conditions accordingly for precision and durability.

Industries That Rely on Custom CNC Turning

1. Aerospace

Precision-turned components like bushings, landing gear parts, and actuator shafts require exacting tolerances and certifications for airworthiness.

2. Medical Devices

CNC turning enables the production of surgical instruments, orthopedic implants, and precision fittings used in medical applications.

3. Automotive

From drivetrain components to engine parts, custom CNC turning delivers strength, precision, and consistency.

4. Electronics

Connectors, housings, and custom heat sinks benefit from the accuracy and repeatability of CNC turning.

5. Oil & Gas

Parts such as valve bodies, couplings, and nozzles must withstand extreme conditions and are commonly made using CNC-turned methods.

Advantages of Custom CNC Turning Services

High Precision: Computer-controlled cutting ensures repeatable and consistent outcomes.

Cost Efficiency: Minimal material waste and reduced labor costs through automation.

Fast Turnaround: Capable of producing parts quickly for urgent orders or time-sensitive projects.

Scalability: From one-off parts to high-volume production runs.

Customization: Fully tailored machining for specific industry or product requirements.

Quality Assurance and Inspection

Leading CNC turning service providers invest in rigorous quality control systems. This often includes:

CMM (Coordinate Measuring Machine) inspection

In-process inspection with digital gauges

Final inspection reports and certifications (ISO 9001, AS9100, etc.)

Traceability of materials and processes

Design Support and Engineering Collaboration

Custom CNC turning providers often offer design-for-manufacturing (DFM) guidance to help clients optimize part designs for CNC processes. Engineering collaboration can lead to:

Reduced production costs

Improved manufacturability

Better performance of the final part

Elimination of unnecessary complexity

Surface Finishes and Secondary Processes

Custom CNC-turned parts can undergo a variety of finishing processes:

Anodizing

Plating (zinc, nickel, chrome)

Powder coating

Polishing and deburring

Heat treating

Engraving or laser marking

These finishing options enhance appearance, functionality, corrosion resistance, and wear resistance of the machined components.

Choosing the Right CNC Turning Service Provider

When selecting a provider for custom CNC turning, consider the following factors:

Experience with similar materials and parts

Range of machines and capabilities

Certification and quality standards

Lead times and scalability

Communication and engineering support

Customer reviews and reputation

Working with an experienced, reliable partner ensures that your project will meet specifications, deadlines, and budget expectations.

Conclusion

Custom CNC turning services play a vital role in modern manufacturing by offering highly accurate, flexible, and efficient solutions for producing complex and critical components. With the right provider, you gain access to cutting-edge technology, skilled machinists, and streamlined production processes tailored specifically to your project's needs.

Whether you're developing a new prototype, scaling up production, or needing high-performance parts for critical applications, custom CNC turning offers the precision, reliability, and versatility required to bring your designs to life.