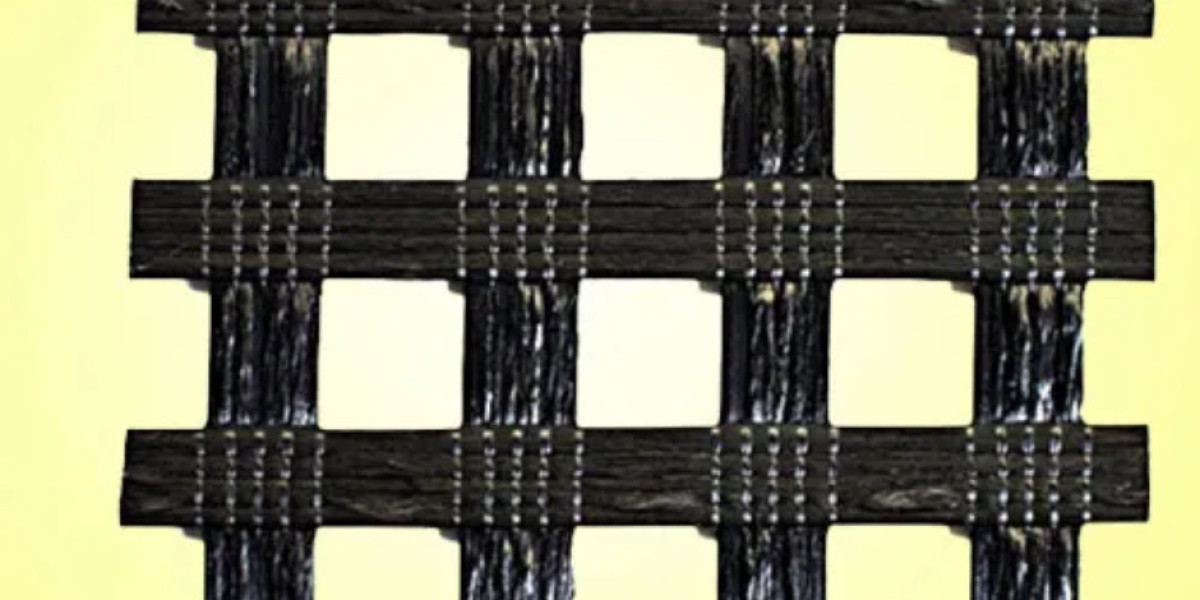

In the realm of civil engineering and construction, the foundation of any project is crucial for its longevity and stability. Often unseen, the materials that provide this strong foundation play a vital role in ensuring the success of various infrastructural developments. One such material that has been gaining prominence for its exceptional properties and versatility is the Polypropylene geogrid suppliers. Singhal Industries, a leader in the manufacturing of flexible packaging products, has been at the forefront of producing high-quality polyester geogrids. This blog delves into the world of polyester geogrids, exploring their benefits, applications, and why Singhal Industries is a trusted name in this field.

Understanding Polyester Geogrids

Polyester geogrids are high-strength, synthetic grids made from polyester fibers. These grids are designed to reinforce soil and other materials, providing added stability and strength to a wide range of construction projects. The primary function of polyester geogrids is to distribute loads more evenly, reduce deformation, and enhance the overall performance of the structures they support.

Key Benefits of Polyester Geogrids

1. High Strength and Durability

Polyester geogrids are known for their exceptional tensile strength and durability. They are capable of withstanding heavy loads and harsh environmental conditions, making them ideal for various applications in civil engineering and construction.

2. Enhanced Soil Reinforcement

One of the primary advantages of polyester geogrids is their ability to reinforce soil. By providing additional support to soil structures, geogrids help prevent soil erosion, reduce settlement, and improve the overall stability of the construction.

3. Resistance to Chemicals and UV Radiation

Polyester geogrids are resistant to a wide range of chemicals and UV radiation. This makes them suitable for use in environments where exposure to chemicals or prolonged sunlight is a concern, ensuring long-term performance and reliability.

4. Cost-Effective Solution

Compared to traditional reinforcement materials, polyester geogrids offer a cost-effective solution. Their lightweight nature reduces transportation costs, and their durability minimizes the need for frequent replacements, resulting in overall cost savings.

5. Easy Installation

Polyester geogrids are easy to install, requiring minimal specialized equipment and labor. This ease of installation translates to quicker project completion times and reduced labor costs.

Applications of Polyester Geogrids

1. Road and Highway Construction

Polyester geogrids are extensively used in road and highway construction. They provide reinforcement to the base and subbase layers, reducing rutting and extending the lifespan of the pavement. This results in safer and more durable roads.

2. Railway Track Bed Stabilization

In railway construction, polyester geogrids are used to stabilize the track bed. By distributing the loads more evenly, geogrids help prevent track deformation and ensure smooth and reliable railway operations.

3. Retaining Walls and Slopes

Polyester geogrids are widely used in the construction of retaining walls and slopes. They provide the necessary reinforcement to hold back soil and prevent landslides, ensuring the stability of the structures.

4. Landfill and Waste Management

In landfill and waste management applications, polyester geogrids are used to reinforce the base and cover layers of landfill sites. This reinforcement helps prevent differential settlement and ensures the stability of the landfill structure.

5. Embankment and Foundation Stabilization

Polyester geogrids are used to stabilize embankments and foundations in various construction projects. By providing additional support to the soil, geogrids help prevent settlement and improve the overall stability of the structures.

6. Mining and Tunneling

In mining and tunneling applications, polyester geogrids are used to reinforce the walls and roofs of tunnels. Their high strength and durability make them suitable for use in harsh mining environments.

Singhal Industries: Leading the Way in Polyester Geogrid Production

Singhal Industries has established itself as a leader in the production of high-quality Polyester geogrid Manufacturers. Here’s why Singhal Industries is a trusted name in this sector:

1. Commitment to Quality

Singhal Industries adheres to stringent quality control measures to ensure that every polyester geogrid meets the highest standards of performance and durability. This commitment to quality ensures that customers receive reliable and long-lasting products.

2. Innovative Solutions

The company is dedicated to innovation, continually developing new products and improving existing ones to meet the evolving needs of various industries. Singhal Industries leverages advanced manufacturing techniques and cutting-edge technology to stay ahead of the curve.

3. Sustainability Focus

Singhal Industries prioritizes sustainability in its operations, from sourcing raw materials to the manufacturing process. By using eco-friendly practices and promoting the recyclability of polyester geogrids, the company contributes to a greener future.

4. Customer-Centric Approach

With a focus on customer satisfaction, Singhal Industries provides personalized solutions and excellent customer service. They work closely with clients to understand their specific requirements and deliver products that meet their needs.

Case Studies: Real-World Applications of Polyester Geogrids by Singhal Industries

Case Study 1: Enhancing Road Durability

A municipal government sought a solution to improve the durability of a heavily trafficked road that was prone to rutting and deformation. Singhal Industries provided high-strength polyester geogrids for reinforcing the base and subbase layers of the road. The result was a significant reduction in rutting and an extended lifespan for the road, leading to improved safety and reduced maintenance costs.

Case Study 2: Stabilizing Railway Tracks

A railway construction company needed to stabilize a track bed to prevent deformation and ensure smooth operations. Singhal Industries supplied polyester geogrids that provided the necessary reinforcement to the track bed. This solution resulted in enhanced track stability and reduced maintenance requirements, ensuring reliable railway operations.

Case Study 3: Reinforcing Retaining Walls

A construction firm required reinforcement for a series of retaining walls in a residential development. Singhal Industries delivered polyester geogrids that provided the needed support to the retaining walls, preventing soil erosion and ensuring the stability of the structures. The project was completed successfully, with the retaining walls remaining stable and durable over time.

Future Trends and Innovations in Polyester Geogrids

The future of polyester geogrids is promising, with ongoing advancements aimed at enhancing their performance and sustainability. Here are some anticipated trends and innovations:

1. Enhanced Material Properties

Research is underway to develop polyester geogrids with enhanced material properties, such as increased tensile strength and improved resistance to environmental factors. These advancements will further expand the range of applications for geogrids.

2. Sustainable Manufacturing Practices

Innovations in manufacturing practices will focus on sustainability, with an emphasis on reducing the carbon footprint of polyester geogrid production. This includes using recycled materials and minimizing energy consumption during the manufacturing process.

3. Smart Geogrids

The integration of technology into polyester geogrids, such as embedded sensors for monitoring structural performance, will provide additional functionality and enhance the overall performance of geogrid-reinforced structures.

4. Customized Solutions

Continued research in material science will lead to even more customized polyester geogrid solutions tailored to specific project requirements, enhancing their functionality and performance in various applications.

Conclusion

Polyester geogrid india have become an indispensable material in the field of civil engineering and construction, offering unparalleled strength, durability, and sustainability. Singhal Industries has set the benchmark for quality and innovation in the production of polyester geogrids, providing solutions that meet the diverse needs of their customers. As the demand for sustainable and efficient reinforcement materials grows, polyester geogrids will continue to play a crucial role in shaping the future of construction, infrastructure, and environmental protection.

By choosing polyester geogrids from Singhal Industries, businesses and consumers alike can enjoy reliable, cost-effective, and environmentally responsible solutions. The future of polyester geogrids is bright, with ongoing advancements and innovations ensuring that they remain at the forefront of material excellence and sustainability.

FAQS

What are polyester geogrids used for?

Polyester geogrids are used in civil engineering and construction projects to reinforce soils and stabilize slopes. They provide strength and stability to the ground, reducing the risk of erosion and enhancing the overall durability of structures.

How do polyester geogrids work?

Polyester geogrids work by distributing loads over a wider area of soil, thereby increasing the bearing capacity of the ground. They restrain lateral movement of soil particles, preventing soil erosion and maintaining the integrity of paved surfaces like roads and parking lots.

What are the advantages of using polyester geogrids?

Some advantages include high tensile strength, resistance to biological degradation, and durability in harsh environmental conditions. They are also lightweight and easy to handle during installation, making them cost-effective for various engineering applications.

Where are polyester geogrids typically installed?

Polyester geogrids are commonly installed in road construction, embankments, retaining walls, and landfills. They are also used in drainage applications to enhance the performance of drainage systems by stabilizing underlying soils.

Are there different types of polyester geogrids?

Yes, polyester geogrids come in various types based on their manufacturing processes and specific engineering requirements. Some types include uniaxial geogrids (designed for strength in one direction), biaxial geogrids (providing strength in both directions), and high-modulus geogrids (used for demanding applications requiring extra strength and stiffness).