Manufacturing today is all about efficiency, smart investments, and reducing operational expenses without compromising quality. Whether it's automotive production, chemical processing, food manufacturing, or hydraulic machinery — companies are constantly looking for ways to optimize performance. One component that has stood the test of time for affordability and durability is the gear pump.

These pumps may look like a simple mechanical device, but they bring significant value to industrial systems. From energy savings to reduced downtime, the cost-saving advantages of using gear pumps in manufacturing are worth exploring. In this blog, we'll take a deep dive into why gear pumps continue to be a smart and economical choice for manufacturers around the world.

What Makes Gear Pumps So Cost-Efficient?

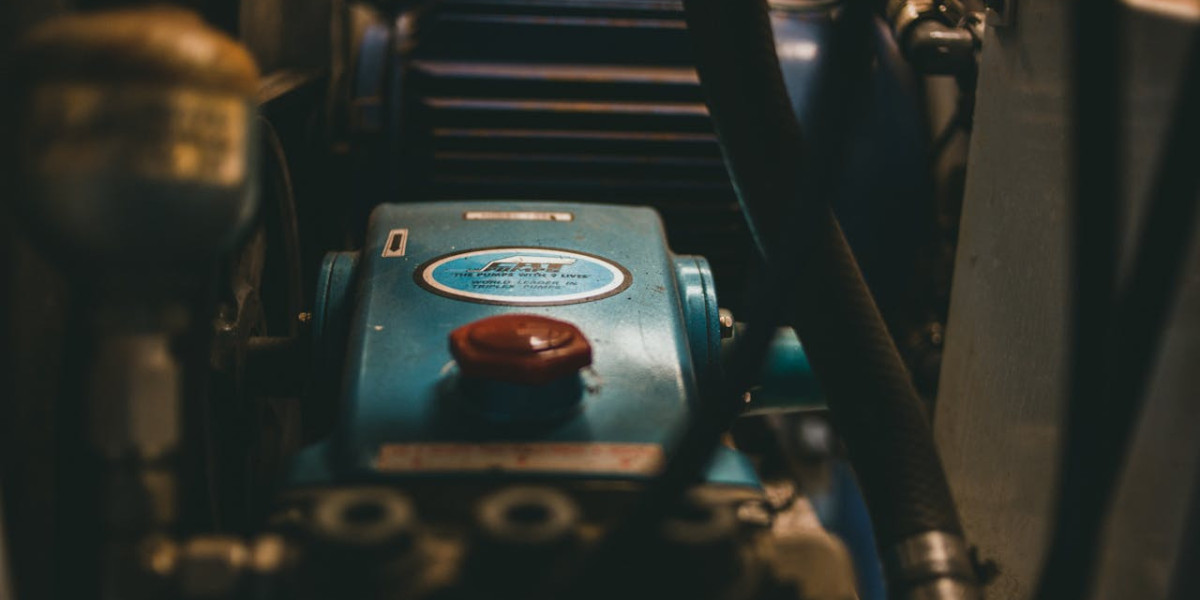

Before we explore the financial benefits, let's understand what sets gear pumps apart. They operate using two or more rotating gears that create a steady flow of fluids. Their design is compact, easy to maintain, and built for long-term use.

Where many pumps require complex assemblies or sensitive handling, gear pumps offer simplicity that still delivers precision. This basic yet dependable mechanism forms the foundation of their cost efficiency in manufacturing environments.

Lower Initial Investment

Manufacturers always consider upfront purchase cost while selecting any equipment. Gear pumps are known for:

Simple design

Fewer components than other pump types

Lower raw material and production cost

Because of these reasons, gear pumps come at a relatively affordable price, especially when compared to high-end centrifugal or screw pumps. For startups or businesses scaling operations, they offer an economical entry point without sacrificing performance.

Long Service Life = Lower Replacement Costs

Manufacturers prefer equipment that works reliably for years. Gear pumps are built from robust materials like cast iron or stainless steel, and they have fewer vulnerable parts. This means:

- Less wear and tear

- Very low risk of mechanical failure

- Stable performance over years

Thanks to their solid structure, gear pumps in manufacturing have a longer operational life, reducing the frequency — and cost — of replacement.

Easy Maintenance Helps Cut Downtime

Unexpected downtime can cost a manufacturing facility thousands of dollars per minute. One of the biggest money-saving benefits of gear pumps is their simple maintenance routine.

Here's what makes servicing them cost-friendly:

- No complex electronics or sensors

- Easily accessible internal gears

- Quick inspection and part replacement

- Minimal specialized labor required

Maintenance teams can diagnose issues quickly, ensuring machines stay running and downtime stays limited. When equipment doesn't stay idle, productivity remains high — automatically improving cost efficiency.

Energy Efficiency That Reduces Utility Bills

Manufacturers constantly battle rising energy prices. Because gear pumps deliver a constant, smooth flow at relatively low power consumption, they are an excellent choice for energy-sensitive operations.

Gear pumps allow users to:

- Achieve steady pressure with minimal power input

- Avoid energy spikes common in complex pumping systems

- Reduce waste in hydraulic operations

Even a small percentage of electricity saved across multiple machines can bring a noticeable drop in monthly bills. Over time, that adds up to substantial cost savings.

Versatility Reduces Need for Multiple Pumps

Another huge advantage is one pump for many applications. Gear pumps can handle a wide variety of fluids, including:

- Oils

- Lubricants

- Fuels

- Paints

- Chemicals

- Thick, viscous fluids

This versatility allows manufacturers to use the same pump type across different operations, instead of buying different pumps for specific materials. Fewer pump models mean:

Less inventory expense

Fewer spare parts required

Streamlined staff training

A smart setup that saves both money and storage space.

Precision Flow Control Prevents Product Waste

Consistent flow and accurate fluid delivery are crucial for sectors like food processing, chemical dosing, and lubrication in machinery. Gear pumps are excellent at:

- Maintaining constant flow rate

- Delivering fluids without pulsations

- Reducing product wastage

When less raw material is wasted, production becomes leaner and more economical. Better fluid control also improves product quality — another indirect financial advantage.

Reduced Risk of Leaks Means Safer and Cheaper Operation

Leaks can be costly — especially when handling high-value chemicals or oils. Gear pumps are built with tight clearances, which means:

- Less fluid loss

- Lower spill cleanup costs

- Reduced environmental and safety risks

Improved sealing not only protects workers but also contributes to budget-friendly operations by minimizing wasted materials.

Compatibility with Automation Lowers Labor Expense

Today, manufacturing efficiency is closely tied to smart automation. Gear pumps are easy to integrate into automated systems because they:

- Offer predictable performance

- Work seamlessly with sensors and control units

- Require minimal operator intervention

Automation reduces manual effort and labor cost. It also ensures continuous and optimized output — bringing better ROI in the long run.

Real-World Savings: How Manufacturers Benefit

Let's look at a few practical scenarios where gear pumps in manufacturing create direct cost reductions:

Manufacturing UseCost-Saving AdvantageHydraulic systems in automotive plantsLower energy consumption and long service lifeLubrication in heavy machineryReduced downtime and breakdown repairsChemical or paint transferLess product waste and leakageFood and beverage processingConsistent flow ensures quality and reduces rejection rate

Across diverse sectors, operational savings remain a consistent benefit.

A Sustainable Investment for Future Growth

Cost-saving isn't just about money — it's also about operational stability. Gear pumps help manufacturers:

Maintain smooth workflow

Avoid expensive shutdowns

Enhance machine lifespan

Improve product quality

These small but powerful advantages support sustainable growth. A one-time purchase can deliver ongoing value for years, making gear pumps a smart financial decision for cost-conscious industries.

Final Thoughts

When every second and resource counts, gear pumps prove their worth in manufacturing environments. They provide a rare combination of affordability, reliability, energy efficiency, and versatility. Manufacturers using gear pumps gain financial benefits not just initially but throughout the equipment lifecycle.

If you're looking to upgrade or optimize your production line, choosing gear pumps isn't just about improving performance — it's about cutting unnecessary expenses and boosting profitability.

Gear pumps may be simple, but when it comes to cost-saving advantages in manufacturing, they truly deliver smarter results for smarter industries.